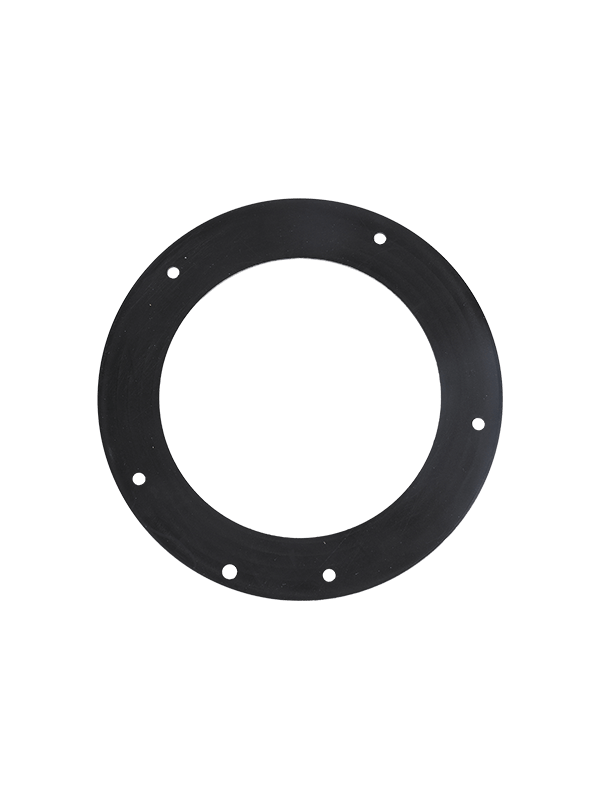

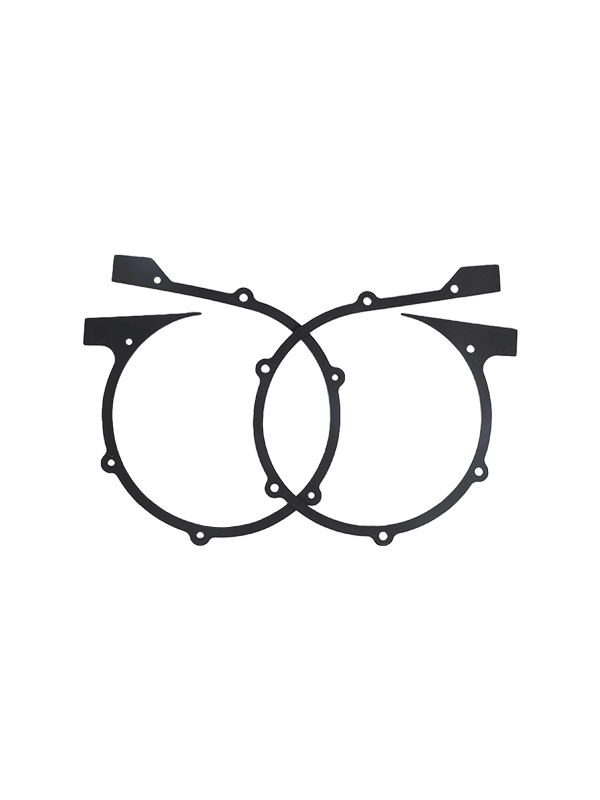

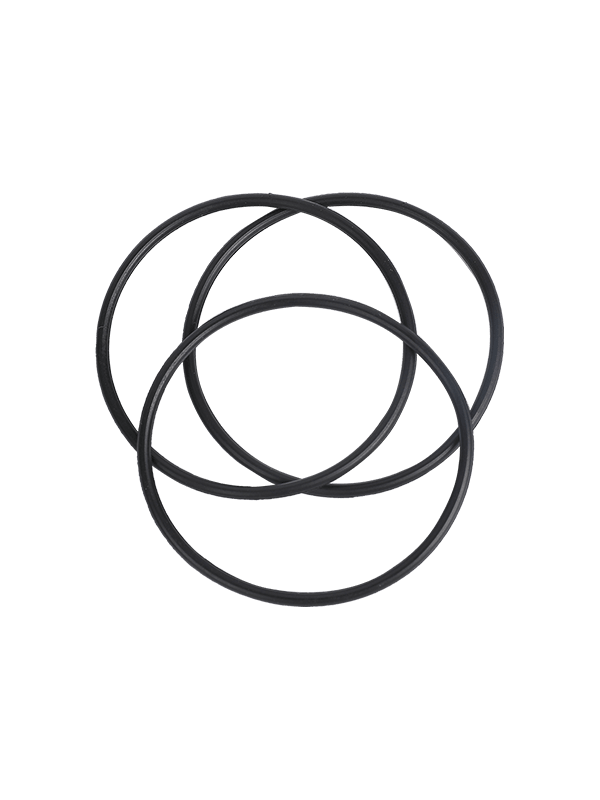

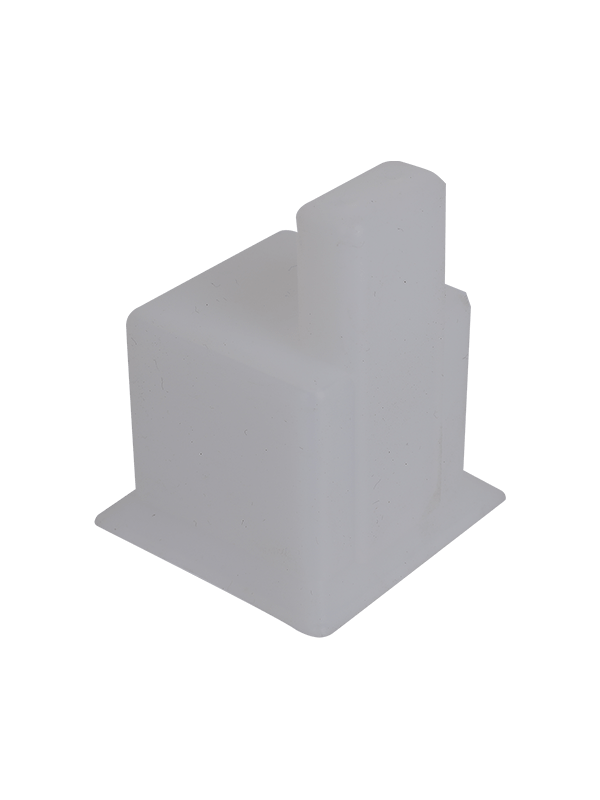

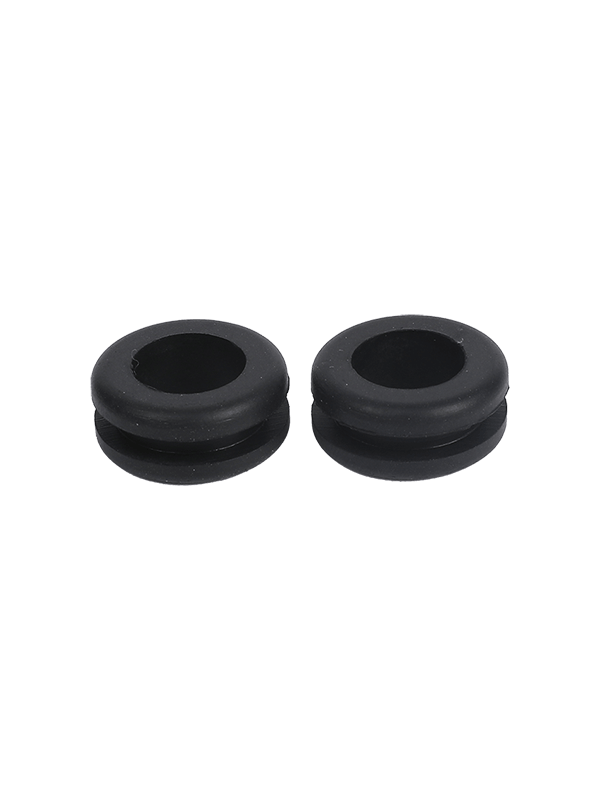

Common problems with silicone rubber ring seals include:

Leaks: If the seal is not installed or maintained properly, it can result in leaks. This can be caused by improper installation, wear and tear, chemical damage, or improper sizing.

Deformation: Over time, the seal may become deformed due to the pressure or temperature of the application. This can lead to leaks or reduced effectiveness of the seal.

Compression set: If the seal is compressed for an extended period of time, it may not return to its original shape when released. This can cause leaks or reduced effectiveness of the seal.

Hardening or softening: Exposure to extreme temperatures or chemicals can cause the silicone rubber material to harden or soften, which can affect the sealing properties of the seal.

To solve these problems, the following solutions may be considered:

Proper installation: Make sure the seal is installed correctly and according to the manufacturer's instructions. Ensure that the seal is the right size and shape for the application.

Regular maintenance: Regularly inspect the seal for wear and tear, deformation, or compression set. Replace the seal if necessary.

Material selection: Choose a seal material that is suitable for the application's temperature, pressure, and chemical exposure.

Use of lubricants: Applying a lubricant to the seal can help prevent deformation and improve sealing properties.

Adjustment of pressure or temperature: If the seal is being deformed due to high pressure or temperature, adjusting these factors may help prevent deformation.

It's important to regularly monitor and maintain silicone rubber ring seals to ensure their effectiveness and prevent leaks in the application. If you encounter persistent problems with the seal, seek advice from a professional.

We are a professional Silicone Rubber Products Manufacturers. If you are interested, you can click the official website to contact us. We are willing to answer more information about the products for you.