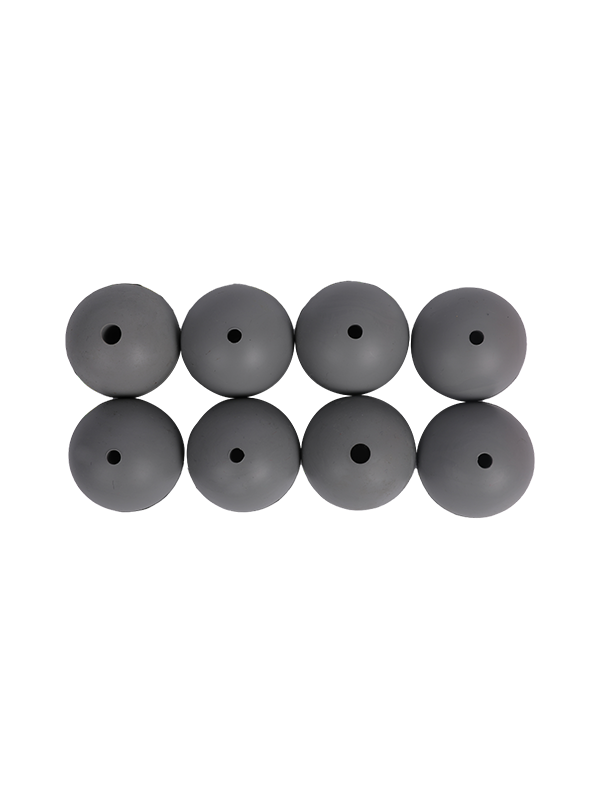

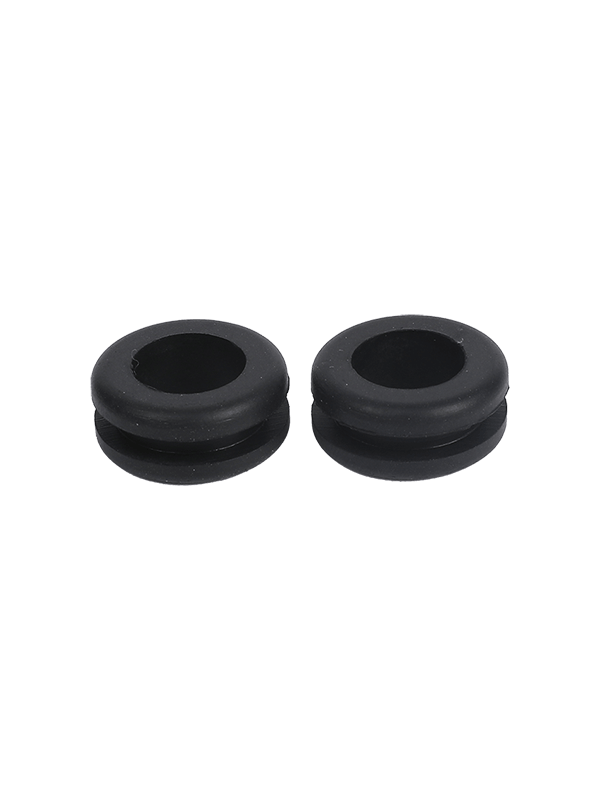

The effectiveness of shockproof

rubber pads in reducing vibrations and impact depends on various factors, including the specific application, the type of rubber material used, the design of the pads, and the conditions under which they are employed. Here are some

considerations regarding their effectiveness:

Material Selection:

Different rubber compounds and materials exhibit varying levels of elasticity, resilience, and damping properties. The choice of material is crucial in determining how well the pads can absorb and dissipate energy.

Durometer Hardness:

The durometer hardness of the rubber influences its stiffness. Softer rubber with lower durometer values tends to be more effective in absorbing vibrations and impact compared to harder rubber.

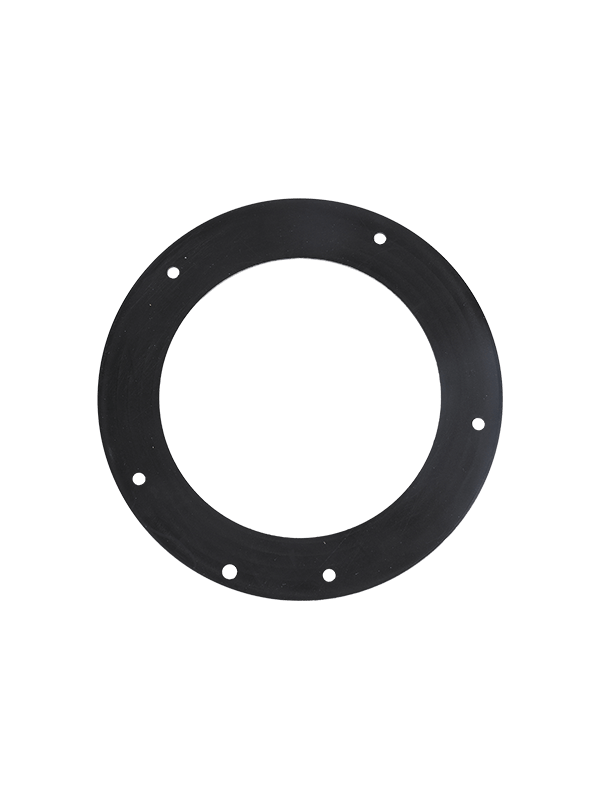

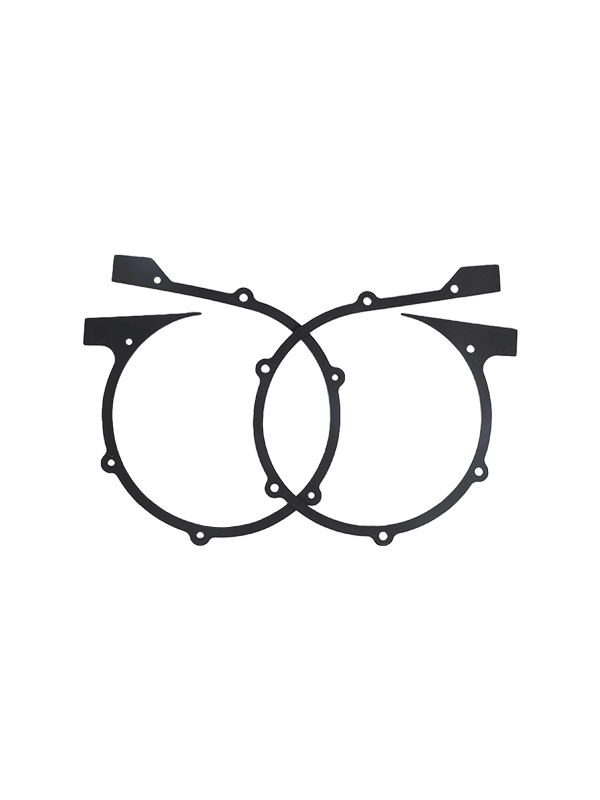

Design and Thickness:

The design of the rubber pads, including their shape and thickness, plays a role in their shock absorption capabilities. Thicker pads generally have more material to absorb energy, but the design must be optimized for the specific application.

Load Capacity:

The load capacity of the rubber pads is important for determining their ability to support and absorb the forces exerted on them. Properly matching the load capacity to the application is crucial for optimal performance.

Compression and Rebound Properties:

The ability of the rubber to compress under load and rebound after deformation is significant. A balance between compression and rebound properties is essential to ensure effective shock absorption without transmitting excessive forces.

Frequency of Vibrations:

The effectiveness of rubber pads may vary with the frequency of vibrations. Some materials are better suited to absorb high-frequency vibrations, while others excel in low-frequency applications.

Installation Conditions:

Proper installation, including surface preparation and attachment methods, is critical for achieving optimal shock absorption. The interface between the rubber pad and the structure it is protecting should be carefully considered.

Temperature Resistance:

The temperature at which the rubber pads operate can impact their flexibility and performance. Some rubber materials may become less effective in extreme temperature conditions.

Environmental Factors:

Exposure to environmental conditions, such as moisture, chemicals, and UV radiation, can affect the longevity and performance of rubber pads. Weather-resistant and durable materials are often preferred for outdoor or harsh environments.

Application-Specific Considerations:

The effectiveness of shockproof rubber pads is highly application-dependent. Understanding the specific requirements and dynamic forces involved in the application is crucial for selecting the right type of pads.

In general, when properly selected and installed, shockproof rubber pads can be highly effective in reducing vibrations and impact. They are commonly used in a variety of industries to protect equipment, improve stability, and enhance overall operational efficiency. However, it's important to carefully consider the factors mentioned above to ensure the optimal performance of the rubber pads in a given pplication.