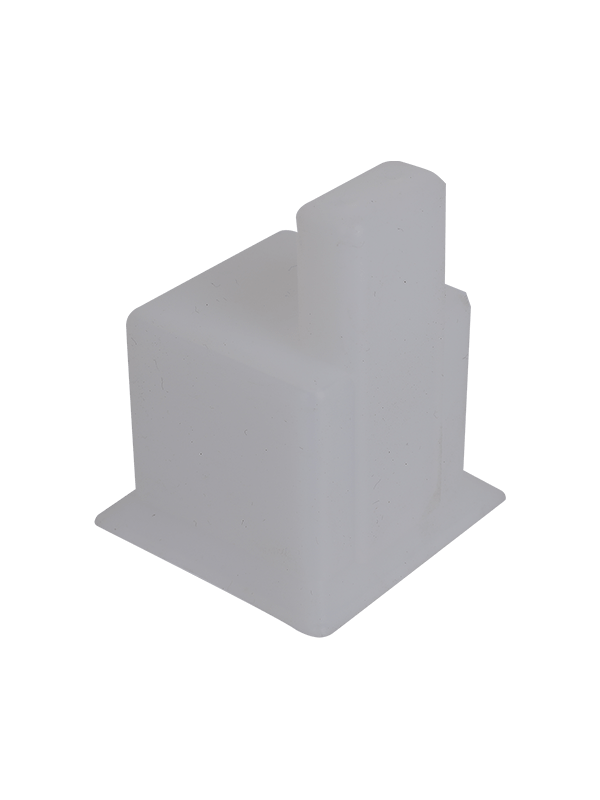

Foam custom silicone is available in soft, medium and firm grades for different levels of compressibility. Interstate die cuts foam silicone rubber for a wide range of applications.

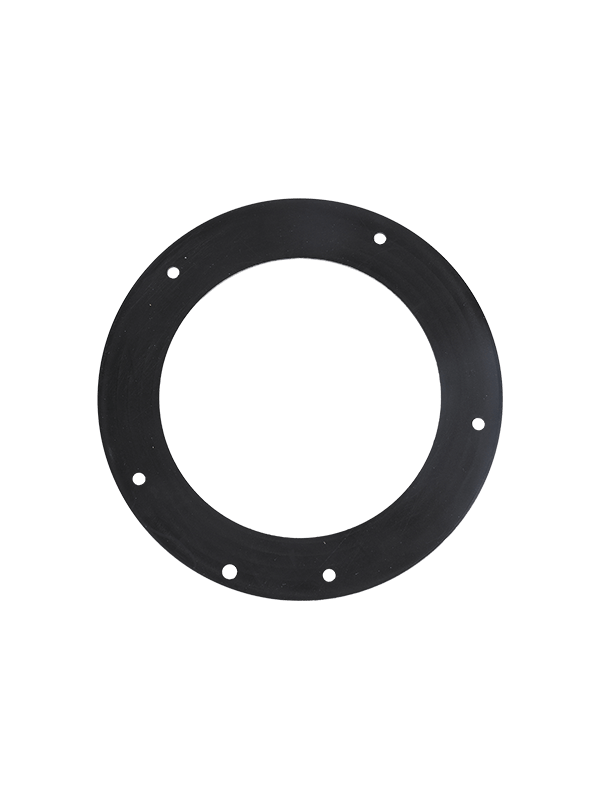

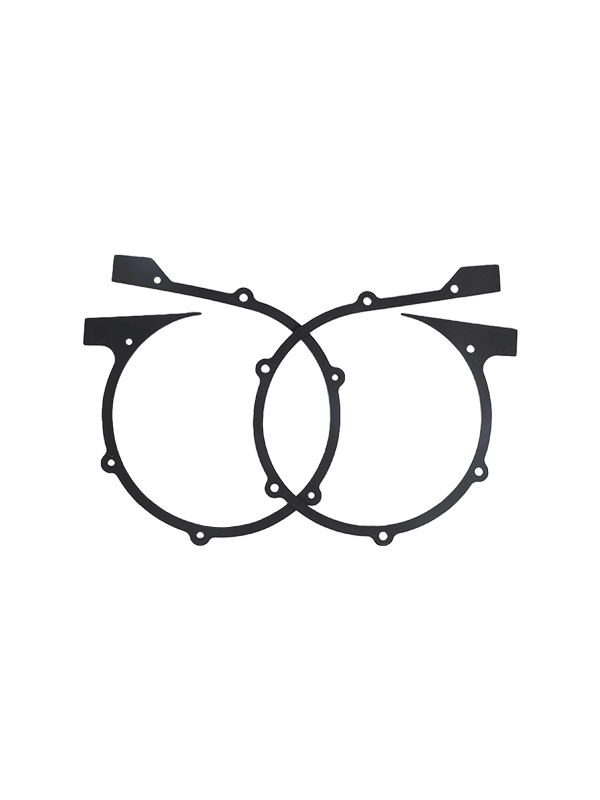

Silicone rubber gaskets resist environmental damage like extreme heat, UV, ozone and mild chemical exposure. They also don’t shrink, which makes them a durable material for industrial applications.

Many silicones offer high flex fatigue resistance – the ability to withstand repeated bending or flexing without cracking. Specialized grades meet aerospace requirements for repeat take-offs and landings. Others are mixed with metal- or silver-coated particles to provide EMI shielding. Conductive silicones are used in communication equipment, and UL 94 silicones meet fire safety testing requirements for electrical enclosures.

Food and beverage equipment manufacturers use FDA-approved silicone rubber that’s odorless, tasteless and resistant to greases and oils. Fluorosilicone rubber is similar to silicone but offers even higher chemical resistance. It also withstands extremely cold temperatures. These characteristics make silicone a desirable material for food and beverage applications.

When it comes to high temperature resistance, silicone gaskets really shine. This synthetic elastomer can withstand extreme temperatures without losing their shape or compressibility, and they’re much more durable than most other materials in this category.

In addition, they can withstand acids, solvents, oils, and other chemicals that would degrade many other types of sealants. This makes them well-suited to outdoor use, such as on radiators, HVAC components, and doors.

Conductive

silicone gaskets are filled with conductive particles, which allow them to provide electrical insulation and shielding against electromagnetic interference (EMI). They can also be made in soft, medium, or firm grades for different levels of compressibility. Some silicone gaskets are even UL 94 V-0 certified, meaning they’re rated to meet flammability and smoke toxicity standards.

Silicone is an effective insulator, and it can seal at high temperatures while preventing leaks in electrical wiring. It also resists oxidation and weathering, making it ideal for use in harsh indoor or outdoor environments.

Its resistance to extreme temperatures and environmental stresses makes it an ideal material for aerospace applications like engine gaskets, vent ducts, and door seals on planes, satellites, and space shuttles. It’s also commonly used in personal, commercial, and industrial vehicles and mass transit systems like buses and trains for HVAC seals, vibration dampening, and radiator seals.

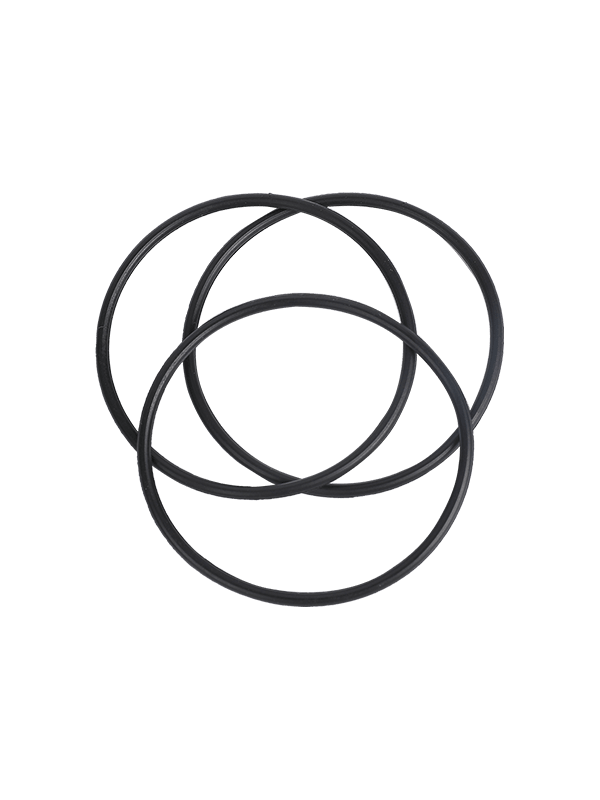

Silicone rubbers can be categorized as solid, sponge, or foam. Solid silicones have a tightly-packed molecular structure and can be hard or soft, depending on the durometer, or level of cross-linking. Interstate die cuts gaskets from a variety of solid and sponge silicones that provide strong environmental sealing with low closure force.

Moisture Resistance

There are a variety of silicone gasket materials available to meet specific design requirements. These include closed-cell sponge that can resist extremely low and high temperatures, and water resistance in both aqueous and steam environments. This material also provides excellent resistance to chemicals, oxygen and ozone.

Fluorosilicone is another option for gaskets that need resistance to hydrocarbons from harsh environmental conditions. It is also resistant to detergents and acetones, and it can withstand high operating temperatures. However, it can be more costly than silicone.

Thermal pads combine the resilience of silicone with cloth to create a stronger and more rugged gasket. They are commonly used for dissipating heat in components. These can be die cut into custom shapes and sizes using computer numeric controlled (CNC) technology.

Food equipment requires gaskets that can withstand extreme heat from commercial ovens and cold temperatures in freezers. Silicone rubber can do both, as well as resist moisture and ozone. The material is physiologically inert, meaning it does not react with many common chemicals.