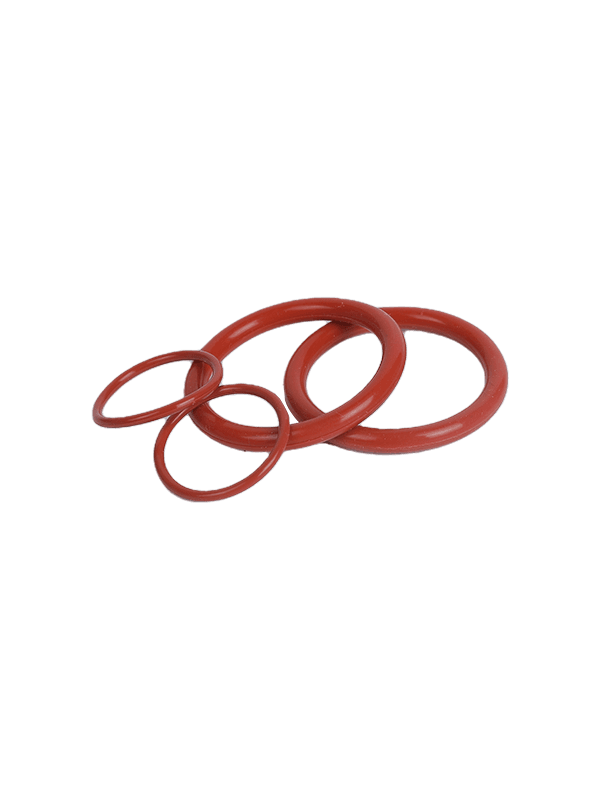

Silicone Sealing Ring are molded products that sit in a groove between two mechanical parts to create an air or liquid-tight seal. They offer great versatility and performance in a wide range of temperatures.

They are also highly pliable and flexible, and have a good resistance to temperature, dry heat, ozone, weathering, acid, chemicals, oil, water steam and flame. These characteristics make silicone an ideal o-ring material for static and dynamic applications.

Its structure is based on a backbone of silicon atoms with alternating oxygen atoms, making it resistant to thermal expansion and more stable than many other rubber compounds. Its organic side chains, however, allow it to be cured in various ways to achieve different properties. Standard o-rings are peroxide-cured, but platinum-cured versions with lower volatile matter can be used in medical systems or other applications that require low leachables and extractables.

Silicone rubber gasket sealing rings are widely used in our daily life. They have outstanding high and low-temperature resistance of silicone, and can still maintain good elasticity at high temperatures. They have a wide range of applications.

1. High reliability, high compressibility, softness and elasticity.

2. It has good oxidation resistance in the air;

3. Outstanding insulating properties; natural tack, no need for additional surface adhesives.

4. Silicone rubber has outstanding high and low temperature resistance, can still maintain good elasticity under high temperatures, has the advantages of ozone resistance and weather resistance, and is suitable for sealing gaskets in thermal machinery.