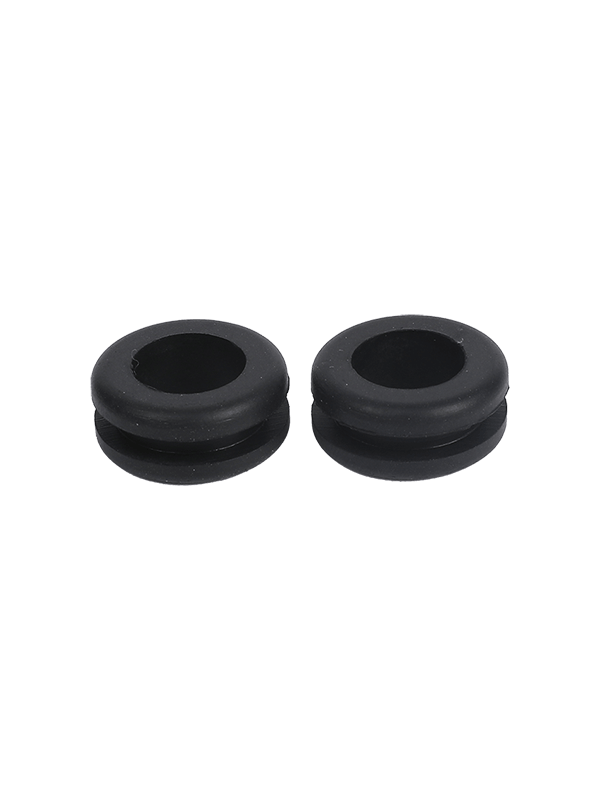

Silicone Rubber Gaskets are a great option for many different industries. They’re a strong, durable, and stable material that works well in harsh conditions. They’re resistant to UV light, ozone, and chemicals. They can be used in a variety of applications, including airplanes, space shuttles, and vehicles.

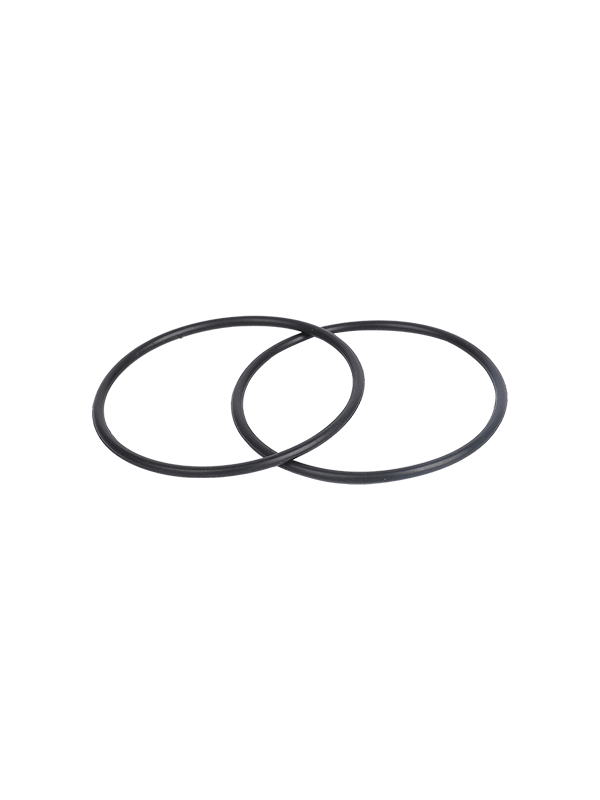

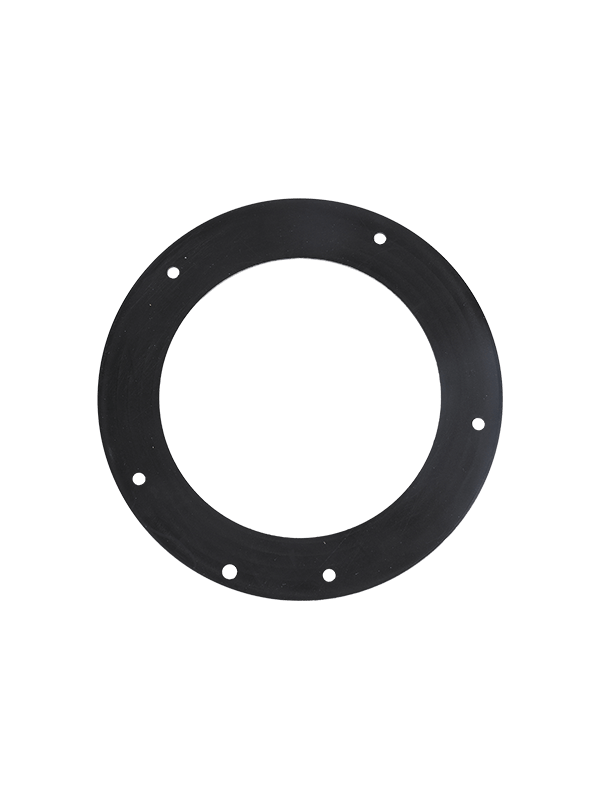

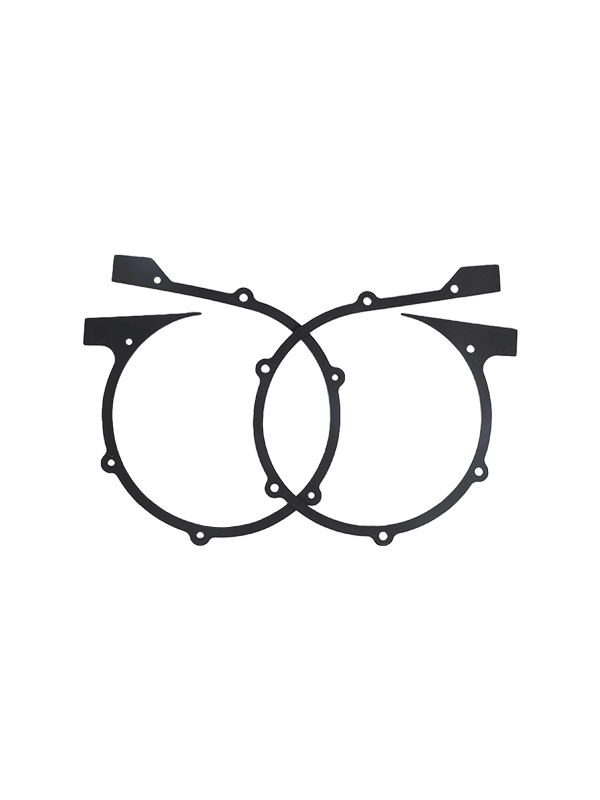

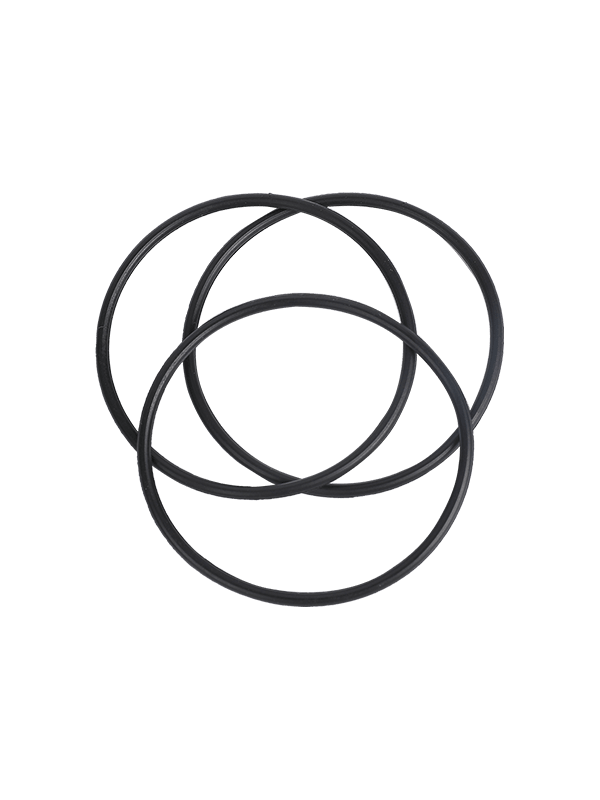

Typical Types of Silicone Gasket:

There are three basic types of silicone gaskets, which include solid silicone, sponge silicone, and foam silicone. Each of these offers unique benefits that can make them ideal for your application.

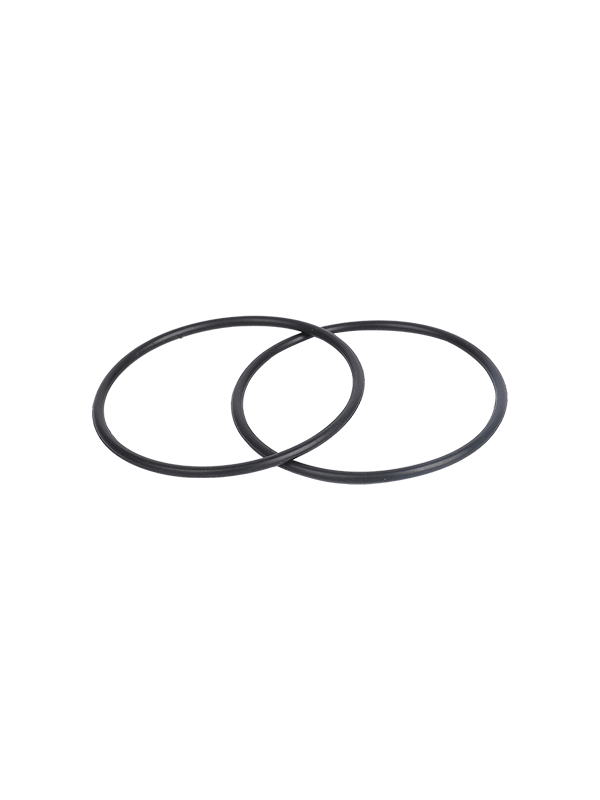

Sponge silicones can be soft, medium, firm, or extra-firm to provide a range of levels of compression. They can also be open-cell or closed-cell.

Foam silicones offer similar compression properties to sponge silicones, and they’re available in soft, medium, firm, or extra-firm grades. They’re available in open-cell or closed-cell, and they can have a temperature threshold of 500 degrees Fahrenheit.

These products are FDA-approved and meet UL 94 standards for fire resistance and safety. They’re also a great choice for food-service processes and medical equipment. They’re also useful for a variety of other applications. In fact, they’re one of the most popular materials used for gaskets. They’re also highly abrasion-resistant, which makes them perfect for medical applications. Plus, they’re odorless and tasteless, so they’re safe for use in the food industry. And they can be produced in sheets or rolls to support a variety of manufacturing processes. You can even get them cut in custom shapes and sizes.