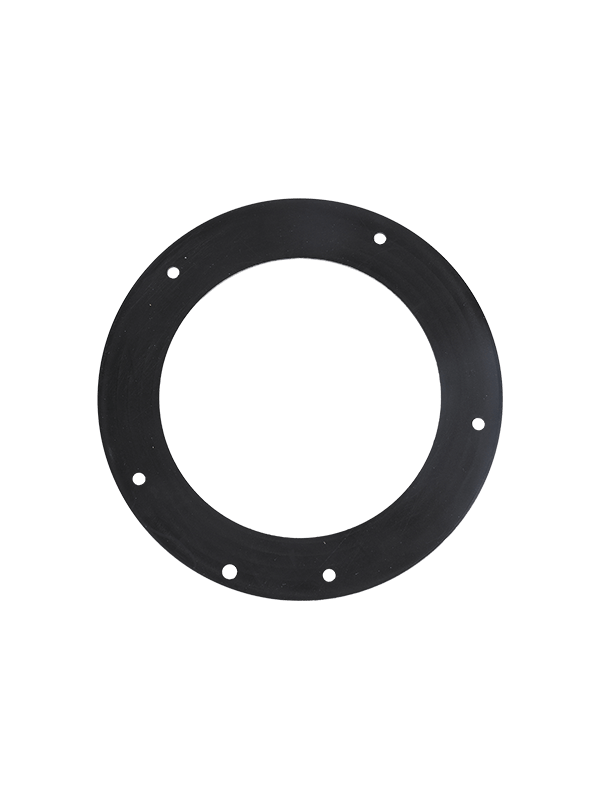

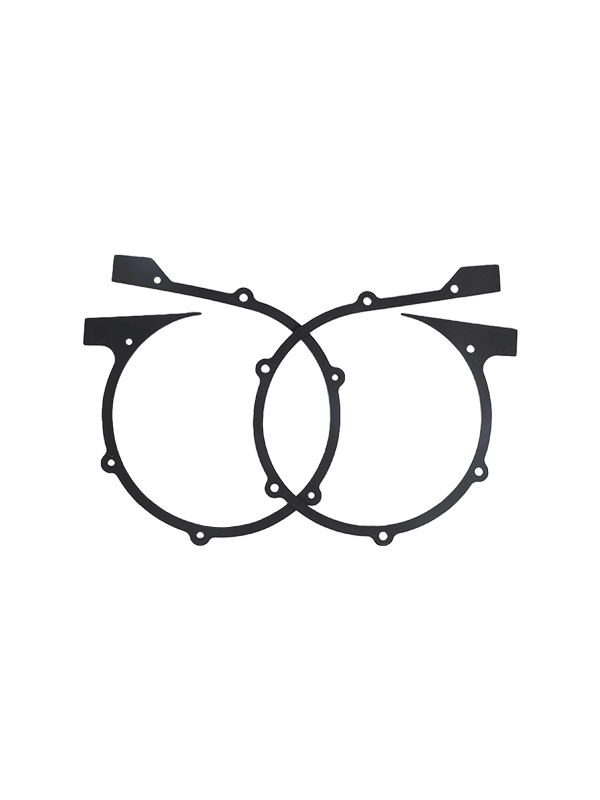

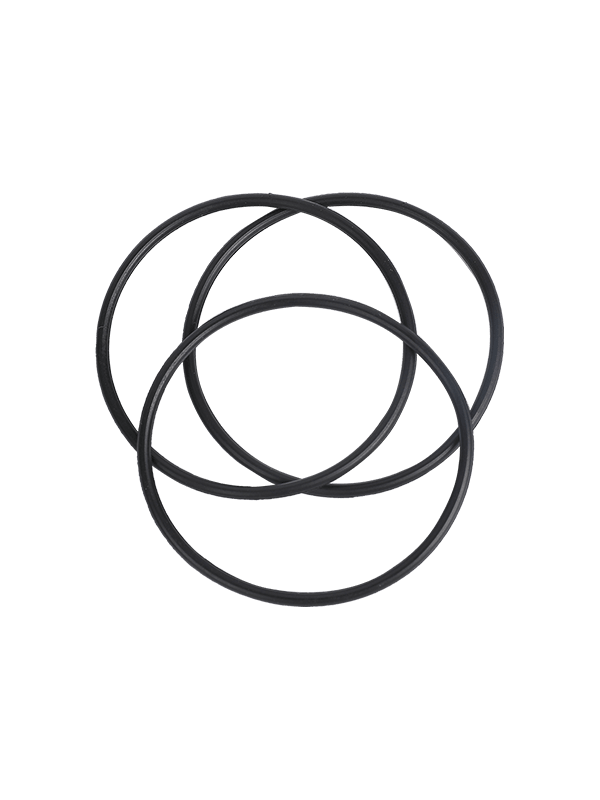

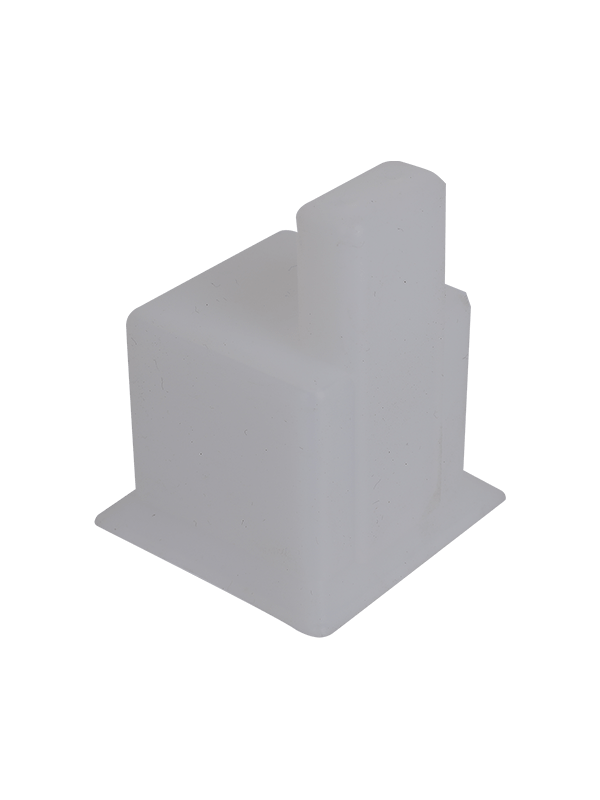

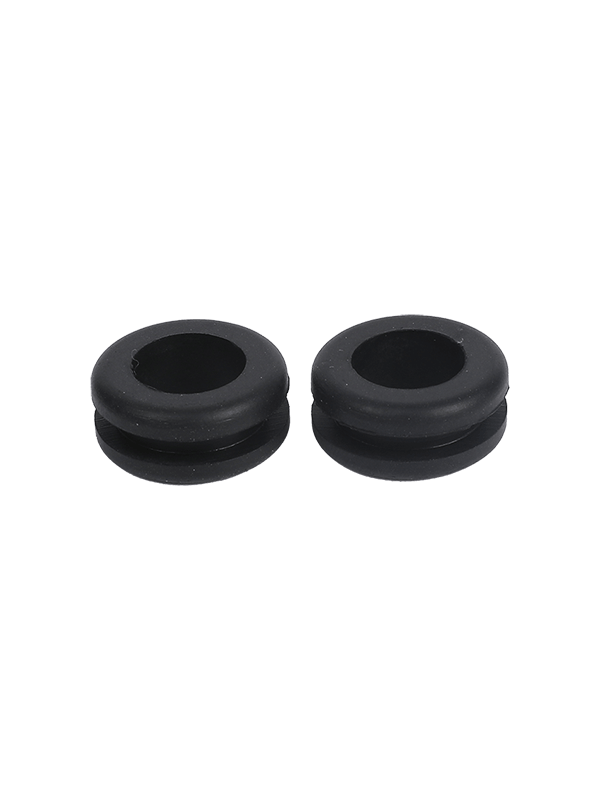

In addition to the general requirements of the sealing ring material, the sealing ring should also pay attention to the following conditions:

(1) Full of elasticity and resilience;

(2) Appropriate mechanical strength, including expansion strength, elongation and tear resistance.

(3) The performance is stable, it is not easy to swell in the medium, and the thermal shrinkage effect (Joule effect) is small.

(4) It is easy to process and shape, and can maintain precise dimensions.

(5) Does not corrode the contact surface, does not pollute the medium, etc.

The most suitable and commonly used material to meet the above requirements is rubber, so most of the sealing rings are made of rubber materials. There are many types of rubber, and new types of rubber are constantly appearing. When designing and selecting, one should understand the characteristics of various rubbers and choose them reasonably.