The shock absorption effectiveness of anti-shock rubber pads is influenced by several factors, and a combination of these elements determines how well the pads can absorb and dissipate shock energy. Here are the key factors that contribute to the shock absorption effect:

Material Composition:

The type of rubber and its composition significantly impact the shock absorption capabilities. Different rubber formulations exhibit varying levels of elasticity, resilience, and damping properties. Common materials include natural rubber, synthetic rubber compounds, and elastomers with additives for enhanced performance.

Durometer Hardness:

Durometer hardness measures the stiffness of rubber. Softer rubber with lower durometer values generally exhibits better shock absorption capabilities. However, the ideal hardness depends on the specific application and the magnitude of the forces involved.

Density and Density Distribution:

The density of the rubber material influences its mass per unit volume. A well-designed rubber pad with an appropriate density can help absorb and dissipate shock energy effectively. Additionally, the distribution of density within the pad can impact how it responds to different levels of shock.

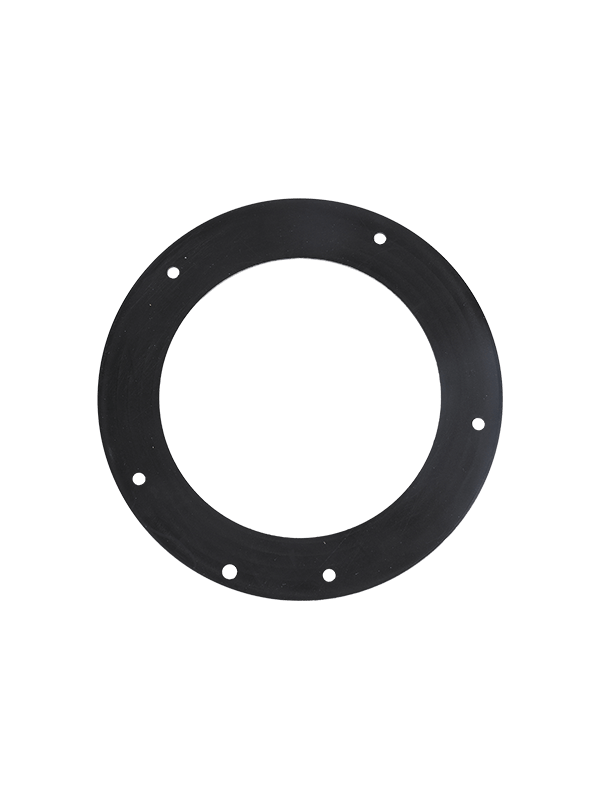

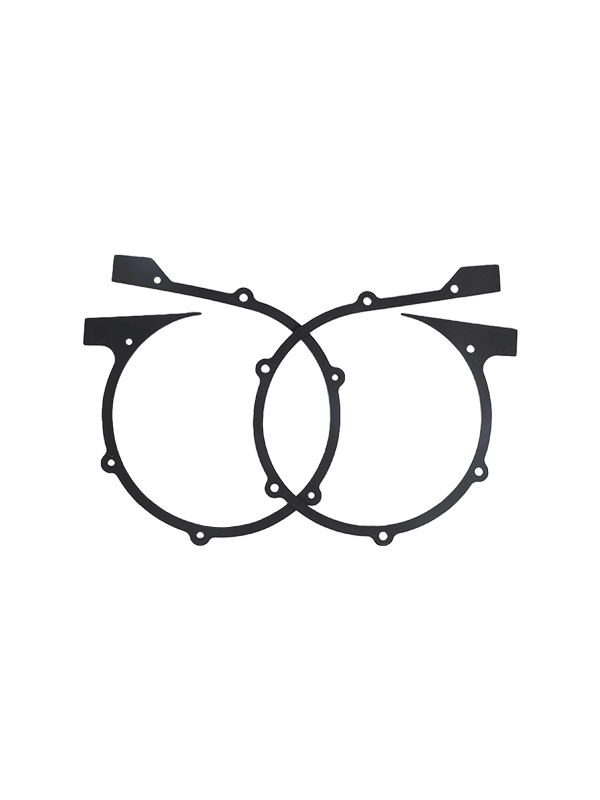

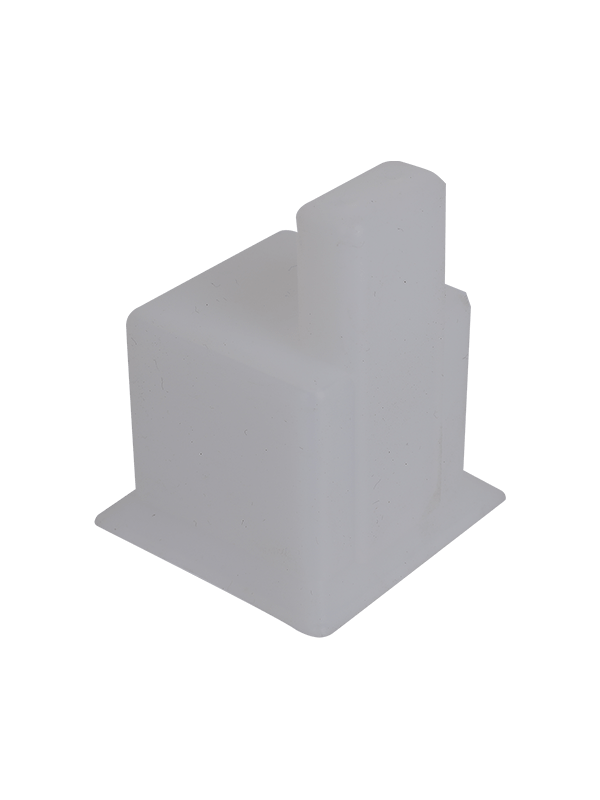

Thickness and Design:

The thickness of the rubber pad and its overall design, including shape and contours, play a role in determining shock absorption. Thicker pads generally have more material to absorb energy, but the design must be optimized for the specific application.

Compression and Rebound Properties:

The ability of the rubber to compress under load and rebound after deformation affects its shock absorption performance. A balance between compression and rebound properties is crucial to ensuring the pad effectively absorbs shocks without transmitting excessive forces.

Temperature Resistance:

The temperature at which the rubber pad operates can influence its flexibility and overall performance. Some rubber materials may become less effective in extreme temperature conditions, impacting their ability to absorb shocks.

Load Capacity:

The load capacity of the rubber pad refers to its ability to support and absorb the forces exerted on it. The design and material selection must align with the expected loads in the specific application.

Frequency of Vibrations:

The frequency of vibrations or shocks can affect how well the rubber pad responds. Some materials are better suited to absorb high-frequency vibrations, while others may excel in low-frequency applications.

Installation Conditions:

Proper installation and contact with surfaces are crucial for optimal shock absorption. The interface between the rubber pad and the structure it is protecting should be considered to minimize energy transfer.

Environmental Factors:

Exposure to environmental conditions, such as moisture, chemicals, and UV radiation, can impact the longevity and performance of the rubber. Weather-resistant and durable materials are often preferred for outdoor or harsh environments.

In summary, the shock absorption effect of anti-

shock rubber pads is a complex interplay of material properties, design considerations, and environmental factors. Tailoring these aspects to the specific requirements of the application is essential for achieving optimal shock absorption performance.