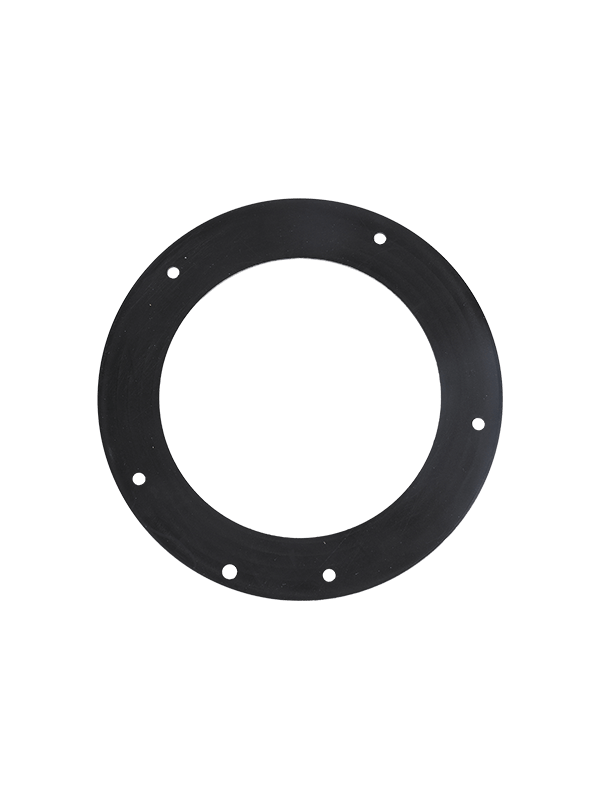

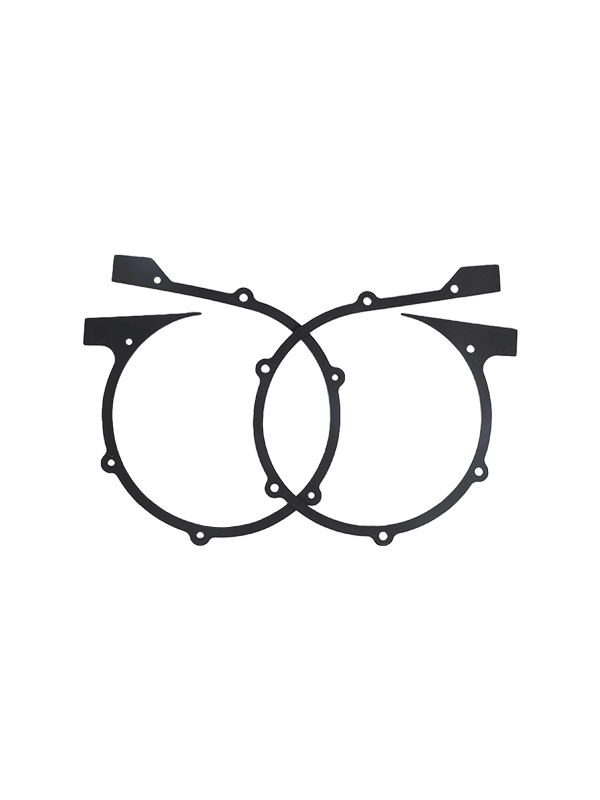

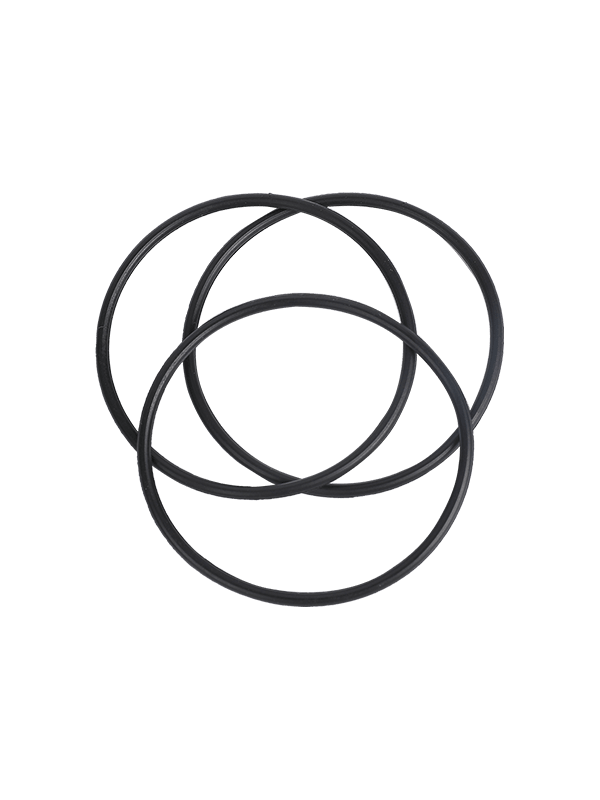

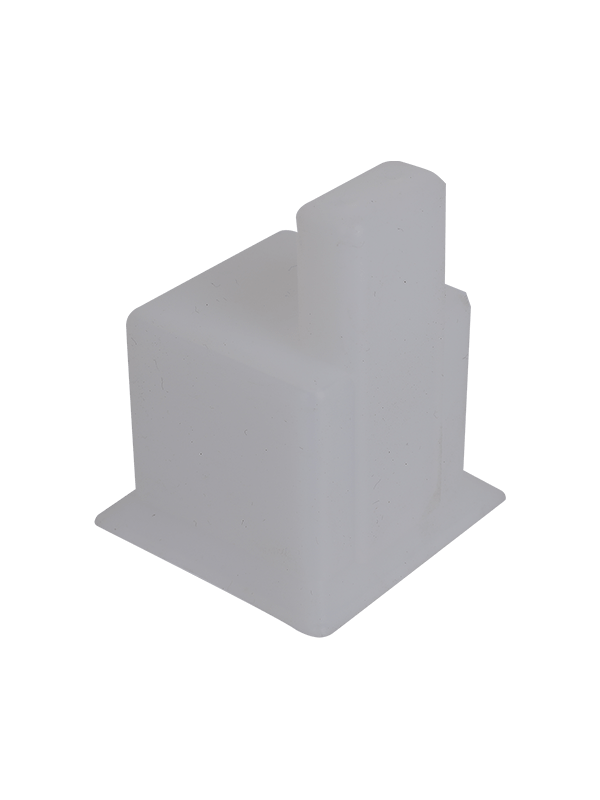

Silicone sealing rings are highly versatile and can effectively seal against a wide range of substances encountered in various industries and applications. Their inherent properties, including flexibility, resilience, and chemical resistance, make them suitable for sealing applications involving liquids, gases, and other media. Here are some types of substances that silicone sealing rings can effectively seal against:

Water and Aqueous Solutions: Silicone sealing rings provide reliable sealing against water and aqueous solutions, making them suitable for plumbing, irrigation, water treatment, and fluid handling systems. They prevent leaks and water ingress, ensuring system integrity and efficiency.

Oils and Lubricants: Silicone sealing rings exhibit excellent resistance to oils, lubricants, hydraulic fluids, and petroleum-based substances. They effectively seal against automotive fluids, industrial oils, lubricating greases, and hydraulic fluids, preventing leakage and contamination in engines, machinery, and equipment.

Chemicals and Solvents: Silicone sealing rings offer resistance to a wide range of chemicals, acids, alkalis, solvents, and corrosive substances. They can effectively seal against harsh chemicals encountered in industrial processes, chemical handling equipment, laboratory apparatus, and chemical storage containers, protecting against leaks and chemical exposure.

Gases and Air: Silicone sealing rings provide a reliable seal against gases, including air, nitrogen, oxygen, and inert gases. They are commonly used in pneumatic systems, gas pipelines, HVAC (heating, ventilation, and air conditioning) systems, and compressed air applications, preventing gas leakage and maintaining system pressure.

Steam and Hot Water: Silicone sealing rings can withstand high temperatures and effectively seal against steam, hot water, and steam condensate. They are used in steam valves, steam traps, boilers, and hot water systems, providing reliable sealing under elevated temperature and pressure conditions.

Food and Beverages: Silicone sealing rings are approved for use in food contact applications and can effectively seal against food products, beverages, and edible oils. They are commonly used in food processing equipment, beverage dispensers, dairy processing machinery, and kitchen appliances, ensuring hygienic and leak-free operation.

Medical and Pharmaceutical Substances: Silicone sealing rings are suitable for sealing medical devices, pharmaceutical containers, and laboratory equipment against fluids, drugs, and biological substances. They meet regulatory requirements for biocompatibility and are resistant to sterilization methods such as autoclaving, ethylene oxide sterilization, and gamma irradiation.

Environmental Contaminants: Silicone sealing rings can effectively seal against environmental contaminants such as dust, dirt, moisture, and airborne particles. They are used in outdoor equipment, automotive components, electrical enclosures, and consumer products to prevent ingress of contaminants and protect sensitive components or assemblies.

Silicone sealing rings offer versatile sealing solutions for a wide range of substances encountered in industrial, commercial, residential, and specialized applications. Their compatibility with diverse media, combined with their durability, flexibility, and chemical resistance, makes them a preferred choice for sealing applications requiring reliability, longevity, and performance.